The first wire drawing die with AI: Vassena & Ailoys announce ground-breaking cooperation

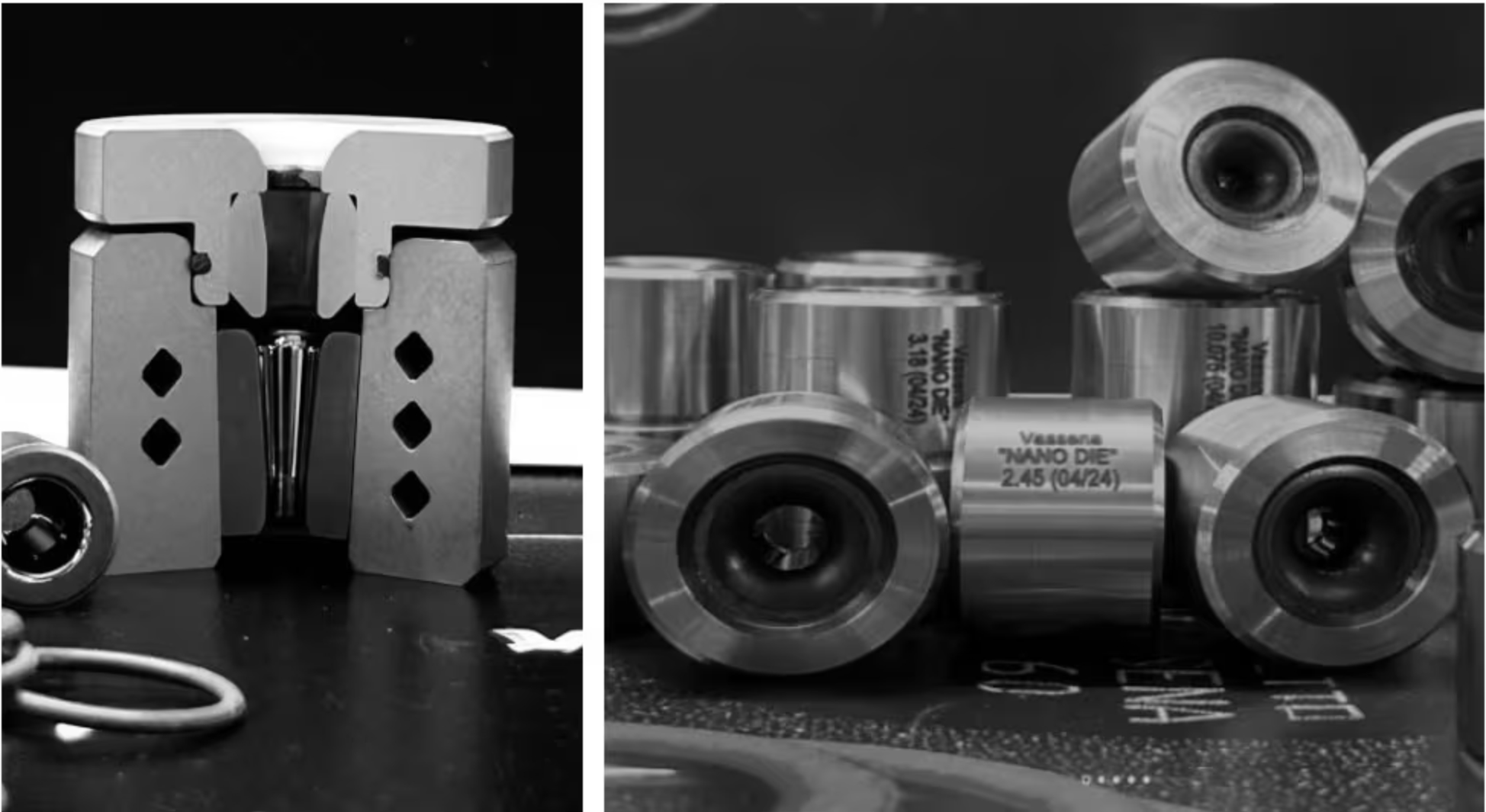

Vassena and Ailoys GmbH, the Berlin-based Industrial AI innovator, have successfully completed a focused roadshow across Northern Italy, engaging leading manufacturers in wire drawing and tube forming. The tour generated multiple requests for quotations, opening the door to strategic cooperations that will help advance manufacturing performance in the region. Ailoys is proud to confirm its first official deployment of its Industrial AI Brain in Italy through a signed strategic cooperation with Vassena Filiere Srl, a leading producer of drawing dies — critical tooling used in wire drawing machines for the production of high-quality wires and cables. Through this cooperation, Vassena will integrate Ailoys’ Industrial AI system into its drawing die production and quality control operations, which oversee the finishing and inspection of each die. This integration will enable every die produced by Vassena to be individually optimized with AI to match each customer’s specific cable requirements. In turn, the performance data of Vassena’s dies will feed directly into the Ailoys Industrial AI system installed by wire drawing manufacturers — creating an additional intelligence layer that boosts efficiency and consistency on the production line. “The warm reception we received in Italy — and the number of quotations requested — confirm that the region’s manufacturers are eager to see AI deliver real, measurable value,” said Sergei Altynbaev, CEO of Ailoys GmbH. “Our strategic cooperation with Vassena Filiere Srl shows exactly how Industrial AI can add precision and true customization to essential tooling, helping wire and cable producers get more performance out of every run. We are glad to announce this first deployment and look forward to building more strong partnerships across Italy.”

“At Vassena, we have always believed that precision tooling is the backbone of quality wire and cable production. By integrating Ailoys’ Industrial AI into our die manufacturing and finishing lines, we can take this precision even further — adapting each die to the exact needs of every customer and process. This partnership allows us to offer our clients a smarter tool that speaks directly to their machines, making wire drawing more stable, more efficient, and more competitive. We see this as a natural evolution for our business and a clear advantage for our partners in the wire drawing industry.”

Ailoys welcomes new industrial partnersBuilding on this milestone, Ailoys GmbH is actively open for cooperation with machine builders, wire drawing manufacturers, and system integrators across Europe. The company invites all forward-thinking stakeholders to join forces in bringing robust, production-ready AI solutions into the metal forming and cable manufacturing industries. With Ailoys’ edge-ready platform, partners can deliver smarter machines, more efficient processes, and measurable competitive advantages — without costly infrastructure changes. To learn more about this partnership and its impact on sustainable manufacturing, visit www.ailoys.com, follow the company on LinkedIn, or contact its sales team in Italy – Dino Poltronieri via email dino.poltronieri@ailoys.com.

About Ailoys GmbH

About Vassena Filiere Srl

|